limitation of vickers hardness test|vickers hardness test procedure pdf : manufacture Vickers hardness test can measure forces outside of the ISO-specified HV 0.01, HV 1, and HV 10 ranges. This ensures that any sample object of a given hardness can be tested. The . 22 de nov. de 2022 · Una de las opciones que están barajando es que invierta en Genesis el mayor bróker de criptoactivos, Binance. Cuando FTX comenzó con problemas hace dos semanas, también hubo un momento en que .

{plog:ftitle_list}

Resultado da Book Atrium Inn Vancouver, Vancouver on Tripadvisor: See 1,692 traveller reviews, 292 candid photos, and great deals for Atrium Inn Vancouver, ranked #60 of 81 hotels in .

Every hardness test has its own advantages and limitations. In this article, the Vicker hardness test with its significance, applications, advantages and disadvantages, is discussed. Several factors are described here for a good understanding of the hardness test.Vickers hardness test can measure forces outside of the ISO-specified HV 0.01, HV 1, and HV 10 ranges. This ensures that any sample object of a given hardness can be tested. The .

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 . There are various methods available for measuring hardness, each with its own set of advantages and limitations. In this blog, we’ll delve into the Vickers Hardness Test and discuss when it’s best to use this method .The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h. One limitation of the Vickers test is its speed. Most international test methods limit how fast the test can be performed so that repeatable results are obtained. Also, some kind of surface preparation is typically required so .

How Does a Vickers Hardness Tester Work? 1. Preparation. 2. Application of Load. 3. Indentation. 4. Measurement. 5. Calculation. 6. Determination of Hardness. 7. Reporting. Advantages of Vickers Hardness Tester. 1. Broad .

In most cases, the Vickers hardness test is used to determine hardness in materials in the micro hardness test load range. However, the Knoop hardness test is often used when hardness testing thin layers, such as coatings, or to .1 Rockwell Hardness. The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth .

Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary to have properly prepared the surface of the .

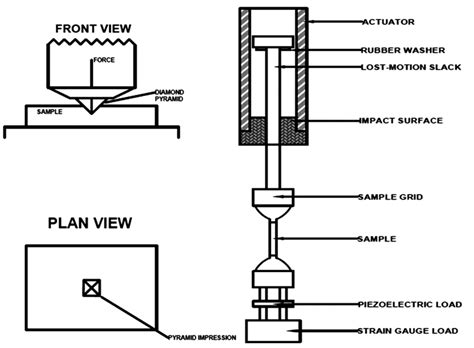

Brinell Hardness The Vickers hardness test utilizes a pyramidal diamond in-denter to create an indentation on the material‘s surface. The diagonals (x and y axis) of the indentation are measured, and . Each method has its advantages and limitations, and the choice of method depends on the material being tested and the .

A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, . The risk of sulphide stress corrosion cracking occurs at even lower hardness and, for this reason, a limit of 248HV is imposed for the root of welds likely to contain sour products. The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface. . Following limitations apply: 1) Standard Hardness Conversion for metals .

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers. Low-load hardness testing is mainly used for testing of small . A Vickers hardness testing machine can share the same components and layouts as Brinelle and Rockwell testers. However, what makes it unique is the use of a universal indenter which allows for ease of maintenance. . Each variant can come with its own set of advantages and limitations and were designed to be used for specific work spaces and .

The Rockwell hardness test and Vickers hardness test are two commonly and widely used techniques among the many hardness testing methods. They can test different types of materials. Rockwell and Vickers hardness tests adopt other principles and testing methods, respectively. They have their own unique advantages and applicable scenarios.Introduction to Vickers Hardness Test The Vickers hardness test, developed in 1921 by Robert L. Smith and George E. Sandland of Vickers Ltd., provides an alternative to the Brinell hardness test with a simpler scale. . Despite some limitations, such as the need for surface preparation, longer test cycles, and higher costs, the Vickers .

Difference between, Brinell,Rockwell and Vickers Hardness Test What is Hardness? Hardness is the property of a material that enables it to resist plastic. Difference between, Brinell,Rockwell and Vickers Hardness Test What is Hardness? Hardness is the property of a material that enables it to resist plastic . Limitation in applying the .Wilson VH3100 and VH3300 All-in-One Ordering Part Number Description Request a Quote W3100 Fully-Automatic Vickers tester with macro & micro ranges, Load range 0,05 - 10kgf, High Performance Workstation with DiaMet Enterprise Control software, & 10x and 50x long working distance measurement objectives and overview cameraAerospace Materials and Processes Questions and Answers – Aircraft Materials – Hardness testing – Brinell and Rockwell Hardness ; Testing of Materials Questions and Answers – Indentation Hardness ; Testing of Materials Questions and Answers – Brinell Hardness Test ; Testing of Materials Questions and Answers – Vickers Hardness Test

Before diving into conversions, it’s essential to understand how the Vickers and Brinell hardness tests work. 1. Vickers Hardness Test. The Vickers test uses a diamond pyramid-shaped indenter that presses into the material under a specific load. The Vickers hardness value (HV) is determined by measuring the diagonal of the resulting indentation.

Very hard metals, over 450BHN may also cause the ball to deform resulting in an inaccurate reading. To overcome this limitation a tungsten carbide ball is used instead of the hardened steel ball but there is also a hardness limit of 600BHN with this indentor. Vickers Hardness Test. The Vickers hardness test operates on similar principles to the .1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness testing machines (Part B), and the calibration of standardized hardness test blocks (Part C). Two general classes of standard tests are recognized:

The Wilson VH3300 offers an advanced, fully automated hardness tester for fulfilling both Vickers and Knoop hardness testing requirements. Designed for all users from novice to expert, it utilizes quick and straightforward operation without compromising the flexibility required for advanced applications. The Vickers hardness test is based on the principle of indentation hardness, where a diamond indenter with a square-based pyramid shape is pressed into the surface of the material under a specified load. The .

[1] ISO 6507-4, Metallic materials — Vickers hardness test — Part 4: Tables of hardness values [2] ISO 18265, Metallic materials — Conversion of hardness values [3] ISO 23718, Metallic materials — Mechanical testing — Vocabulary [4] JCGM 100:2008 (GUM 1995 with minor corrections), Evaluation of measurement data - Guide to the expression of uncertainty in .Safety. Our Vickers hardness testers meet all common safety requirements, including limit switches for limitation of the travel distance and collision warning features. During development of our Vickers hardness tester, ZwickRoell .The factors concerned include hardness level (and scale limitations), specimen thickness, size and shape of the workpiece, specimen surface flatness and surface condition, and indent location. The article focuses on the selection for specific types of materials, such as steels, cast irons, nonferrous alloys, and plastics, and industrial .

The Vickers hardness test is a very reliable method for measuring the physical properties of materials. It is a very popular method in engineering, industrial use, and the oil and gas industries. The article is all about the principle and application of Vickers hardness test. + 86 755 61301520; [email protected]; Search. The Vickers hardness test measures material hardness by determining the size of an indentation made by a diamond pyramid-shaped indenter under a specific load. A load ranging from 1 gf to 100 kgf is applied to the material’s surface, creating a square-shaped indentation. After the load is removed, the diagonals of the indentation are measured .V. Limitations of Vickers Hardness Test. Despite all the benefits of the Vickers hardness test method, it has a few drawbacks as well. Some of these drawbacks include that whenever a sample material surface is precoated, the coating thickness may affect the accuracy of measurement. Secondly, it is observed that at lower loads, a level of .

The Monte Carlo simulation (MCS) method for uncertainty evaluation of measurement results has gained popularity as an alternative to the method based on law of propagation of uncertainty (LPU) ever since the recommendation by JCGM through supplement JCGM 101:2008. In this paper, efforts have been made to compute the uncertainty in .Vickers hardness testing is extensively used in the metals and alloys industry to evaluate different metallic materials' hardness, strength, and durability. This instrument helps evaluate metallic components' hardness, strength, and durability, ensuring they meet the required specifications and standards. 2. Automotive and AerospaceThe Wilson VH1150 Macro Vickers Hardness Tester is the ultimate macro-Vickers hardness tester. Boasting a unique load range of 300gf – 50kgf, enjoy its user-friendly operation with automatic load selection and a seamlessly integrated motorized turret in . Note: 1. The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. . Traditional hardness measurement is only applicable to large-sized samples, not only due to limitations of the measuring instrument, but also because the residual indentation cannot accurately reflect the true hardness .

The Vickers hardness tester has a wide measurement range and can measure almost all metal materials used in industry, from very soft materials (several Vickers hardness units) to very hard materials (3000 Vickers hardness units). The value in front of HV is the hardness value, and the latter is the test force.This document specifies the Vickers hardness test method for the three different ranges of test force for metallic materials, including hard metals and other cemented carbides (see Table 1), metallic coatings and other inorganic coatings.. The Vickers hardness test is specified in this document for lengths of indentation diagonals between 0,020 mm and 1,400 mm.

vickers hardness testing machine diagram

vickers hardness test procedure pdf

WEBToriiiaa, _toria_m_, majorlyvictoria, victoria. OnlyFans Instagram Twitter. Follow Discuss 🔥 UNDRESS AI. 🔥 UNDRESS AI. 289 Media. 132 Likes. Next Page .

limitation of vickers hardness test|vickers hardness test procedure pdf